-

Interlocking Stabilized Soil Blocks

Description

Interlocking Stabilized Soil Blocks are brick-like earthen blocks that can be used in place of bricks in most construction applications. Stabilized by compression, cementation, and interlocks, these blocks have a high soil to cement ratio and are capable of bearing significant loads. In addition to these characteristics, Interlocking Stabilized Soil Blocks cure at ambient temperatures. Reducing the amount of cement used reduces project costs. Reducing the amount of bricks consumed conserves acres of trees from being cut down and used for a firing process, which generates more than 20% waste.

Current practices of mixing sand with cement to create blocks, produce permeable blocks which degrade rapidly

Current practices of mixing sand with cement to create blocks, produce permeable blocks which degrade rapidly

Use

We work with local farming households, brickwork operators, builders, community authorities, and entrepreneurs to spread knowledge of ISSB production and use. Interlocking Stabilized Soil Blocks are used in place of traditional bricks, waddle and daub, concrete masonry units, and sun-dried adobe blocks.

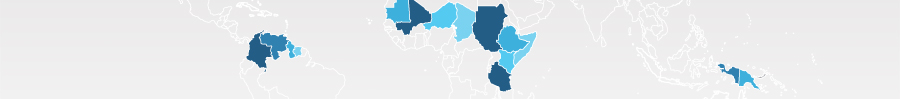

Currently ISSB technology is beginning to spread across East Africa as a sustainable way to construct schools, houses, factories, and cisterns. The Venture Trust ISSB production program emphasizes the use of Interlocking Stabilized Soil Blocks for the construction of water infrastructure (micro-dams, surface catchments, cisterns, channels, etc.). Although simple, this fundamental technology has far reaching impacts on the livelihoods of the people who employ it. We are proud to have the opportunity to add to the growing body of knowledge on ISSBs and the responsibility of introducing it to new communities.

Workers shovel a sand cement mixture into vibrating moulds, which settle the mixture. Blocks made in this way require over twice as much cement as Interlocking Stabilized Soil Blocks when made correctly. Efforts to save money, however, lead blockworks like this to reduce the amount of cement used in the mixing process. The result is a weak permeable block, which degrades quickly in the humid tropical climate.Education

Workshops and training on using the hardware and blocks takes place over a six week period, after which point, Venture Trust assists independent block makers in operational matters. Assistance in operational matters includes training for the construction of cisterns and hydrologic infrastructure. In addition to workshops and monitoring, we promote local block makers as sources for ISSBs for the construction of our Rainwater Harvesters, Surface Water Retention Systems, and Slow Sand Filters.

We ensure that blocks are produced according to international standards, and testing of the blocks takes place with the involvement of fabricators and classrooms, as an example of how standards are set by governments, as well as how to achieve quality and structural standards. Physical tests of the blocks provide a good, hands on example of physical forces such as shear, compression and tension for high school and college students.